Aerogel, an ultra-lightweight and porous solid material, has gained significant attention due to its unique physical properties and broad application prospects. With an extremely low density of typically 3 kilograms per cubic meter, it ranks among the least dense solids in the world.

In materials science, density is a key factor influencing the physical and mechanical properties of porous media. The precise measurement of true density (skeleton density) is crucial for understanding the microstructure of aerogels and optimizing their applications.

The true density of aerogel refers to the mass per unit volume of the solid particles themselves (i.e., the solid skeleton volume). This parameter is essential for comprehending the porous structure of aerogels and enhancing their use in thermal insulation, adsorption, catalyst support, and other fields. True density measurement typically employs the vacuum gas displacement method (gas expansion displacement method), which is based on Boyle's Law (Pv = nRT). This method calculates the skeleton volume by measuring the adsorption and displacement behavior of gases in the sample's pores. Commonly used adsorbents, such as nitrogen and helium, are widely used due to their chemical inertness and low adsorption properties.

The process for determining the true density of aerogel is as follows:

1. Gas Preparation: Adjust the pressure reducer on the helium or nitrogen cylinder to between 0.2 and 0.5 MPa, ensuring the displacement pressure is within the range of 0.07 to 0.115 MPa to obtain accurate test results.

2. Sample Weighing: Take 1-3 grams of aerogel sample and accurately weigh it using an analytical balance with a precision of 0.0001 grams.

3. Test Setup and Analysis: After setting the pretreatment time and instrument stabilization time, click the start analysis button. Once the test is complete, the instrument will automatically save the data and output the results.

To verify accuracy, one can manually mix aerogel samples, measure their true density, and compare the results with theoretical calculations. This method not only validates the instrument's accuracy but also provides reliable data support for practical applications. For example, in the development of thermal insulation materials, precisely measuring the true density of aerogels can optimize their thermal insulation performance, enhancing their effectiveness in aerospace, building insulation, and other fields.

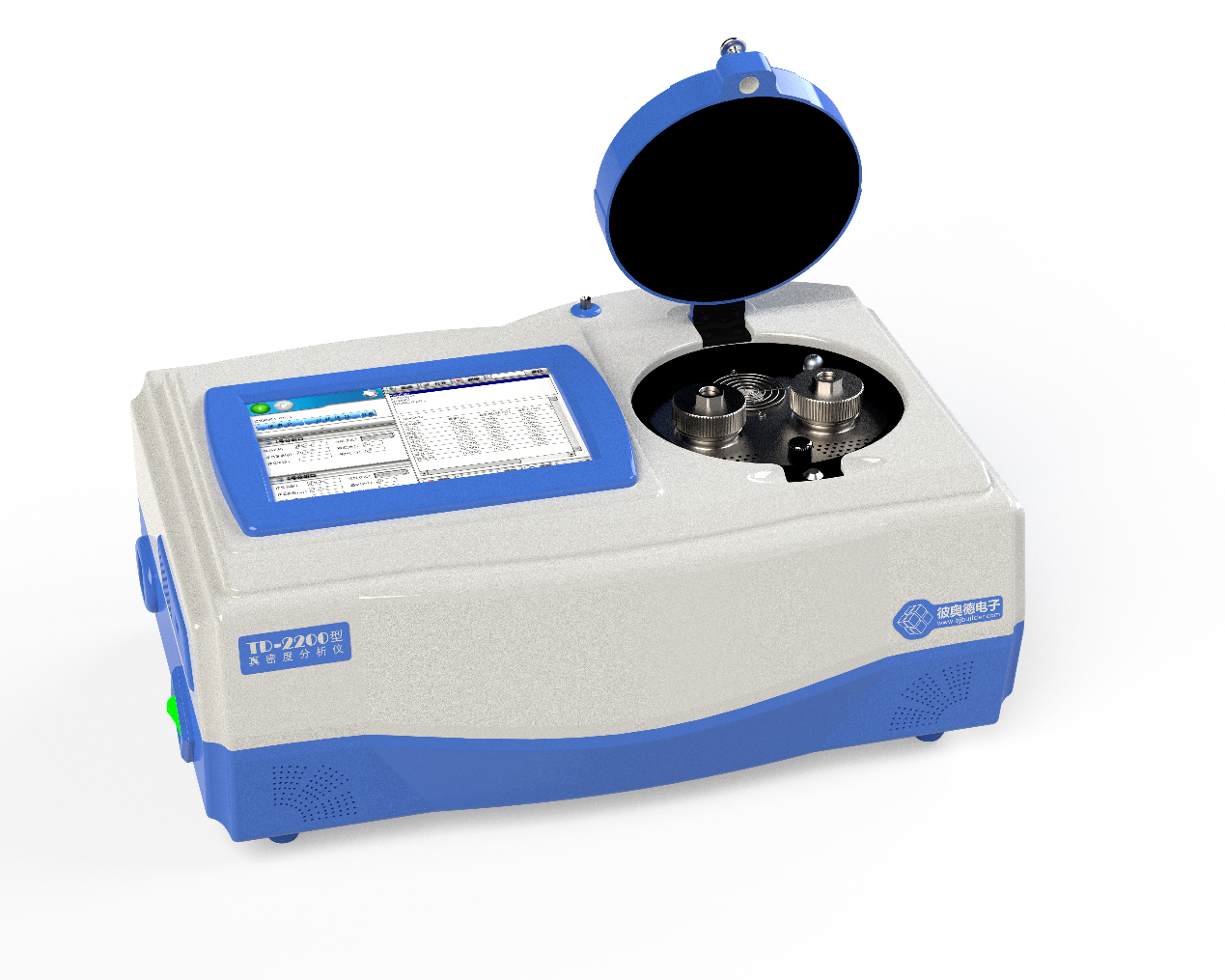

The Beijing Builder TD-2200 true density analyzer is a precision instrument designed for high-accuracy density measurements, particularly suitable for determining the skeletal density of porous materials like aerogels. The upgraded TD-2300 model can meet the needs of material density testing at different temperatures.

1. High-Precision Measurement: Equipped with high-precision pressure sensors and temperature compensation systems, the instrument ensures high accuracy and repeatability of measurement results. It can provide reliable data even at extremely low densities, meeting the testing requirements for ultra-lightweight materials like aerogels.

2. Automated Operation: The instrument features intelligent software that supports automated sample handling, data acquisition, and analysis. From sample weighing to result output, the entire process is automated, significantly improving experimental efficiency and reducing human error.

3. Rapid Testing: With optimized test procedures and an efficient vacuum system, testing time is significantly reduced. The TD series true density analyzers can complete complex density measurements quickly, greatly enhancing experimental efficiency.

4. Flexible Testing Modes: The instrument also supports customizable test parameters to meet the testing requirements of different materials.

5. User-Friendly Interface: An intuitive interface supports one-click operation and automated data processing, making it easy for even new users to quickly master the operation. Detailed instructions and online help documents are also provided for quick user guidance.

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact