Temperature programmed desorption of NH3-TPD ammonia is an experimental method to characterize the acidic site (active site) and acid strength of the catalyst. In this experiment, the catalyst needs to pre-adsorb ammonia gas, and then heat it at a fixed heating rate under carrier gas purging, so that the carrier gas passes through the catalyst bed. The change of NH3 concentration signal at each temperature point was measured, and the chemical signal was converted into electrical signal plot.

1. Catalyst dosage

The catalyst is generally filled with 50 ~ 200mg, the particle size is 40 ~ 80 mesh, the particle size uniformity can ensure the repetition and reliable TPD spectrum.

2. Activation pretreatment

Under the purge of helium or nitrogen, it is raised to a certain temperature for dehydration and activation treatment, and the time is not less than 1h.

For molecular sieves, the activation temperature is generally 400℃ ~ 500℃. The activation temperature should be combined with the nature of the catalyst, the most common treatment temperature is 200-300℃, for some samples with relatively developed pores may choose a higher treatment temperature (300-500℃), for high temperature treatment, it is necessary to pay attention to avoid the precipitation of load material, template agent precipitation and sample structure collapse and decomposition. In particular, if it contains organic solvents that have not been removed, the solvent should be removed with a Muffle oven or oven before testing.

Organic solvent precipitation

3. Adsorbed ammonia

Use low concentration of nitrogen, ammonia or helium ammonia for adsorption at 120℃-150℃, so that ammonia molecules and the catalyst surface reaction, after the adsorption is completed, maintain the current temperature, use helium or nitrogen purge for at least 30 minutes to remove the physical adsorption and residual ammonia in the pipeline.

There are two methods of adsorption, the first is combined with quantitative ring by pulse sampling adsorption, the peak area out of the first pulse is the smallest (or no), with the increase of times, the peak area becomes larger and larger until the peak area remains unchanged, at which time it is considered that the catalyst surface has been saturated by ammonia adsorption. The other is the saturation purging method, even if the ammonia gas continuously purges the catalyst surface, generally at least 1h.

Pulse sampling adsorption

4. Ammonia /NH3 desorption

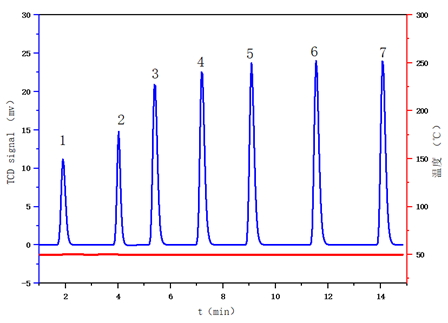

Helium/He gas is used as carrier gas. When the TCD baseline is leveled, it rises to high temperature at a certain heating rate. During the heating process, changes in ammonia concentration are collected, and chemical signals are converted into voltage signals and fed back on the spectrum.

The heating rate is generally 10℃ ~ 20℃/min. If the heating rate is too large, the TPD peak will overlap and the signal will be lost. If the heating rate is too slow, the TPD peak will be weakened and the test time will be extended.

In most experiments, the maximum desorption temperature is generally set at 900℃. For molecular sieve, the TPD peak at high temperature is not an acidic site, so the molecular sieve TPD desorption temperature can be raised to 600 ~ 700℃.

5. NH3-TPD Testing instrument

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact