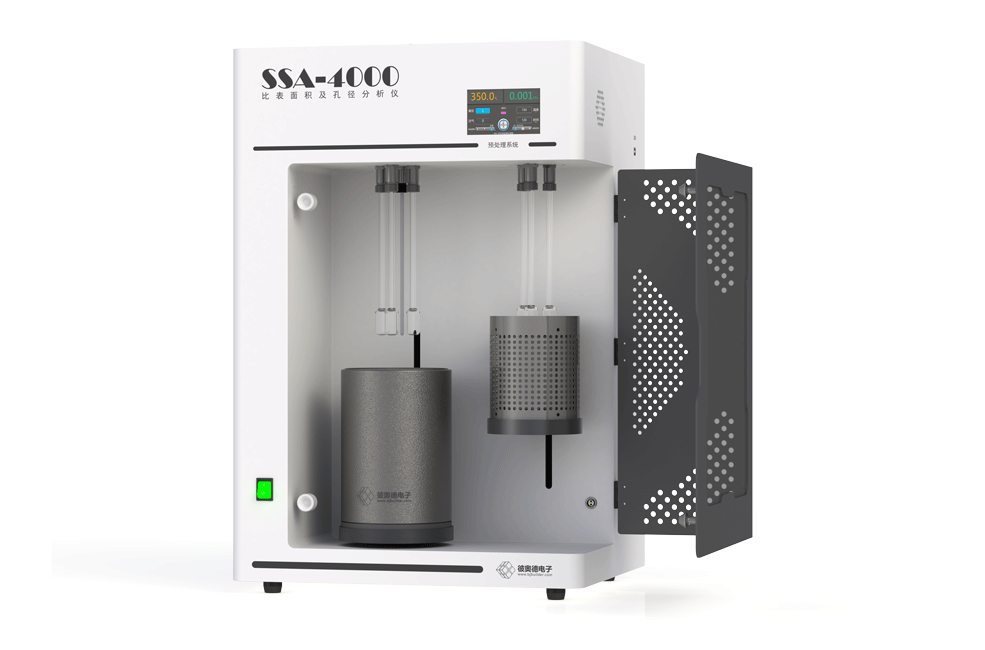

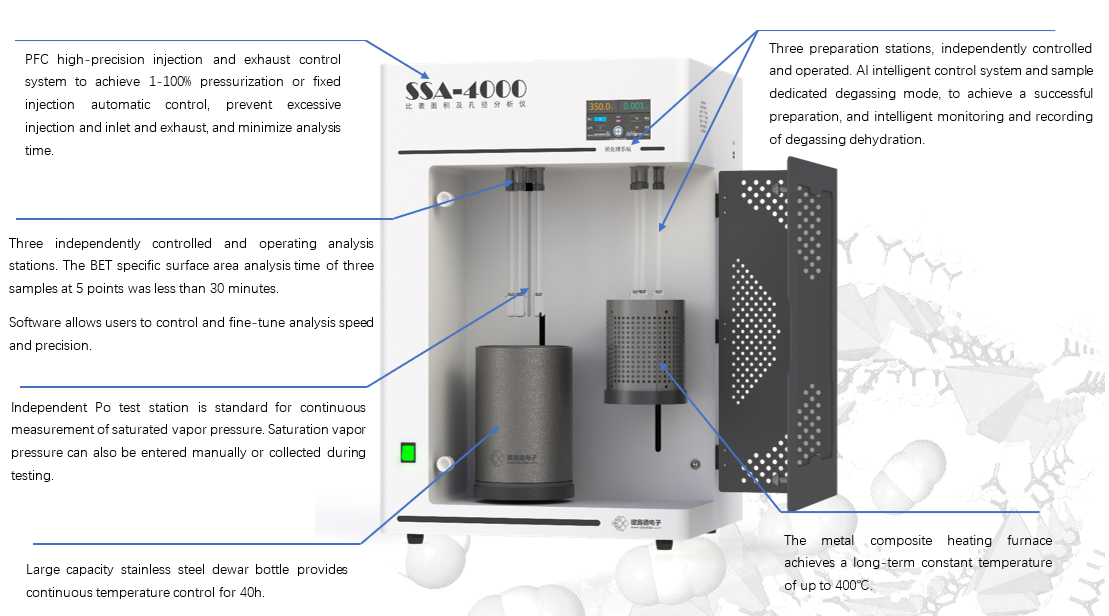

The SSA-4000 series of specific surface area and aperture analyzers produce specific surface area and porosity results quickly and reliably, and the analysis station and degassing station are independent and integrated, saving laboratory space. SSA-4000 series is one of the indispensable tools in material research and quality control with low operating cost, fast analysis speed, simple use and good reliability.

Intelligent Degassing System

Integrated intelligent degassing system, 3-station AI intelligent degassing station, equipped with independent vacuum system, degassing station and analysis station can run synchronously and asynchronously to improve work efficiency. Provide "standard", "ultra-light", "multi-water" and other modes of one-click selection, intelligent judgment of the treatment effect.

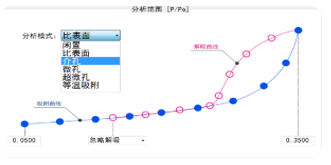

"Fixed Point" and "Constant Pressure" Tests

Arbitrarily set the test pressure range and the number of data points in the test range to shorten the test time. Freely set any P/Po test point, greatly improve data stability.

Exclusive Test Template Settings

In addition to the standard analysis mode of the software, users can customize the test template according to the sample type and call it with one click. It also supports automatic retrieval of analysis parameters from test reports.

Test theory:

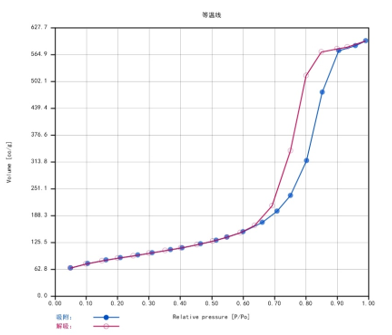

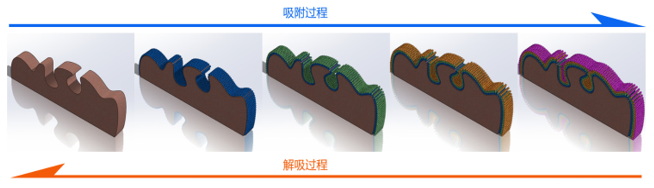

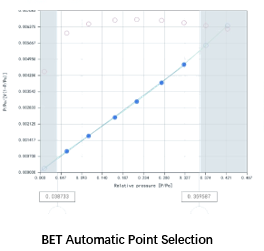

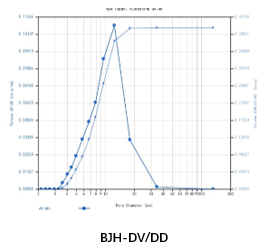

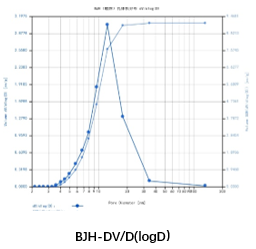

Adsorption and desorption isotherm Gas adsorption curve BET specific surface area measurement Langmuir specific surface area BJH method mesoporous pore volume distribution.

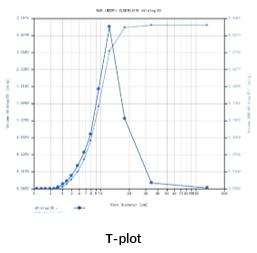

HK/MP/SF method Microhole analysis DR Method Microhole analysis of specific surface area inside and outside t-plot t-plot microhole analysis.

Applications

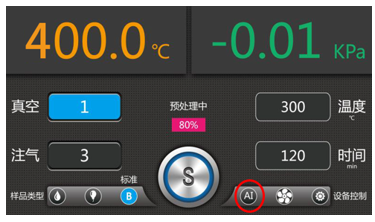

AI intelligent degassing station to solve the problem of sample preparation

1、For the first analysis, it is not clear how long the water in the sample can be cleaned?

▲ One click select "AI" intelligent mode, automatically determine the completion of processing, automatically stop, automatically record the total time, provide accurate conditions for the next preparation, to achieve dehydration "freedom".

2、The sample has a large water content and is easy to "boil/elutriate" under vacuum?

▲One key selection of "multi-water" mode to solve the problem of elutriation preparation failure.

3、How to deal with ultra-fine powder such as Boehmite/alumina, ultra-light powder such as graphene/white carbon black, which is easy to "boil" under vacuum?

▲One click to select "ultra-light" mode to solve the problem of boiling preparation failure.

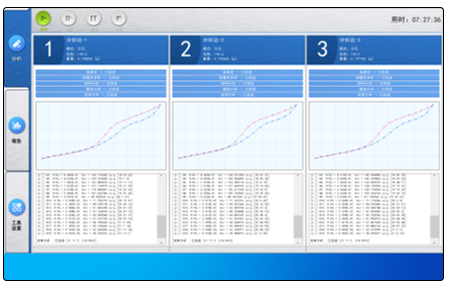

Advanced Control Software, Powerful

◆ Visual display, setting window, in line with the needs of contemporary users, better use experience.

◆ Automatically saves data without worrying about data loss.

◆ Automatically determines the absorption/desorption equilibrium according to the sample adsorption characteristics.

◆ One-key automatic leak detection and automatic calibration.

◆ When a fault occurs, the pop-up prompts you to quickly rectify the fault.

Fast Use of Software, Templates for Different Samples, One Click Call

▲Select the analysis type with one click according to the analysis requirements.

▲Test templates are invoked with one click depending on the material.

▲Provide dozens to hundreds of analysis templates to meet all users.

SSA-4000 Parameters | |

Testing Principles | Static capacity method.(ISO 9277 /ASTM D6556 etc.) |

Precision | Specific surface area/pore size/pore volume/adsorption capacity repeatability ≤ 1%. |

Adsorbate | 77K nitrogen, 87K argon, 273K carbon dioxide, 298K carbon dioxide, etc. |

Test Range | Specific surface area ≥ 0.01㎡/g (nitrogen), pore size analysis 0.35nm-500nm. |

Analysis Station | 3, parallel. |

AI Preparation Station | Same analysis station integrated machine design, independent of each other; Equipped with a heating furnace, with an upper temperature limit of 450 ℃ and a temperature control accuracy of ± 0.01 ℃. Equipped with an independent mechanical pump and pressure sensor One click selection of multi water and ultra light sample degassing schemes; Multiple intelligent degassing solutions: temperature+fixed time; Temperature+AI judgment; Temperature+fixed time+AI judgment. |

Vacuum System | The analysis station is equipped with a two-stage rotary vane vacuum pump; The preparation station is equipped with a two-stage rotary vane vacuum pump. |

Po Testing Station | Independent saturation steam pressure testing station for real-time testing, equipped with independent sensors. |

SSA-4000 Specifications | |

SpecificationsSpecifications | L680mm×W460mm×H820mm,N.W 42.55kg Voltage: 220V Power: 700W Frequency: 50 Hz. |

Humidity | Relative humidity range from 10% to 90%. |

Temperature | -20 ℃~ 50 ℃. |

Dewar Flask | Configure 1 stainless steel Dewar bottle. |

Heating Furnace | Isothermal heating furnace, temperature 450 ℃. |

Pressure Sensor | 3 analysis stations, 1 Po station, 1000torr. |

Test Function | Gas adsorption and desorption isotherms, BET/Langmuir specific surface area, t-plot inner and outer surface area of carbon black, t-plot micropore area/volume, BJH mesoporous pore size/pore area, as mesoporous volume, HK/SF/MP micropores, average pore size, total pore volume analysis, etc. |

Intelligent Software | Intelligent software self inspection and warning, can set P/Po start and end points, and collect quantity; One click calling template, supporting custom exclusive templates. |

Control System | Intelligent touch system, multi-mode one click selection. |

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact